Step 3 or 4

The dyeing process, (depending on what they are making), can happen at three different stages of the process – at the large bundles (Tops), at the thread spools, or piece dyeing (once the yarn has been woven into fabric). The pictures below are the process of dyeing and drying the Tops – they take a long time to complete and go through several different stages.

Some of the dyeing process and the machinery that handles the process.

After the drying process is completed for the Tops, they are funneled into these large barrels so they can be prepped for the first of two spinning stages. They look really heavy but are so light and soft that you can hardly feel them in your fingers.

Step 4

Spinning, which happens in two different phases, making the thread fine enough for weaving. Keep in mind that if they were dying the completed fabric this part of the process would have already happened, making it the 3rd step in the process. There a rows and rows of these spinning machines in a huge room. The processes are continually monitored and the size of the operation is really something to see in person. They even have automated vacuums that run back a forth along the spinning machines that keep the machines dust and debris free (I forgot to take a picture of that because I trying not to get hit by them!).

Step 5

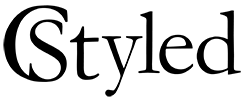

The warping process. This process is critical to get right because the next process is the weaving or adding the “weft” to create the actual fabric. They basically have to attach and position thousands of parallel spools of thread parallel on the giant cylinder called the “beam.” Laser sensors monitor all of the thread as they are wrapped around the “beam” because this becomes the foundation of the weave of the fabric. When I was a kid, my mom used to work as a tapestry weaver. I remember that it would take her hours and hours to do this part by hand because it had to be done just right. Think of it as the concrete foundation of a house. If you don’t get this right, you will have a bunch of problems down the road with the integrity of the building.

Step 6

One of the coolest parts of the process, adding the weft to the warp, or in layman terms, weaving. Now we get to see the fabric come to life right in front of our eyes. I told you earlier about Vitale Barberis Canonico’s commitment to taking care of their employees and here is an example of what I was talking about. The textile machines that weave the fabric are really noisy and they realized that it was causing hearing issues with the staff that worked in this area. So, they created sound proof cabins to house the machines that you can see from this view. There are a lot of machines in this room which can be really loud. In addition to the soundproof cabins, employees are required to wear ear plugs – we even put in before entering in the room.

[

These weaving machines are pretty amazing. How simple or complex the fabric pattern is determines how fast the needle eye passes back an forth passing above and below the vertical threads. Speeds can vary from 600-1000 passes per minute. So fast you can’t see the needle eye moving back and forth but you can see the resulting fabric being made right before your eyes. Check out the still picture and the short video clip below

Step 7

The Finishing part which I didn’t get to see in action. They have expert menders that review and correct by hand any defects in the cloth. After, the non-winter fabrics go through a delicate burning process to eliminate stray threads. You can’t see the actual flames but it is happening in the first picture with the machines. The winter fabrics are soaked in hot, soapy water, softening their shine and lends to consistency. Additional finishing processes include stretching on rollers, pressing through large cylinders, and steaming in order to reduce swell in the threads (shown in the pictures below).

Now that the fabric has been made, the process is not over. They have to cut, label, package, and store the rolls for the various companies that are purchasing the newly made fabrics. The part of the storage room that I could see and photograph doesn’t give you a real sense of the scale of what they do.

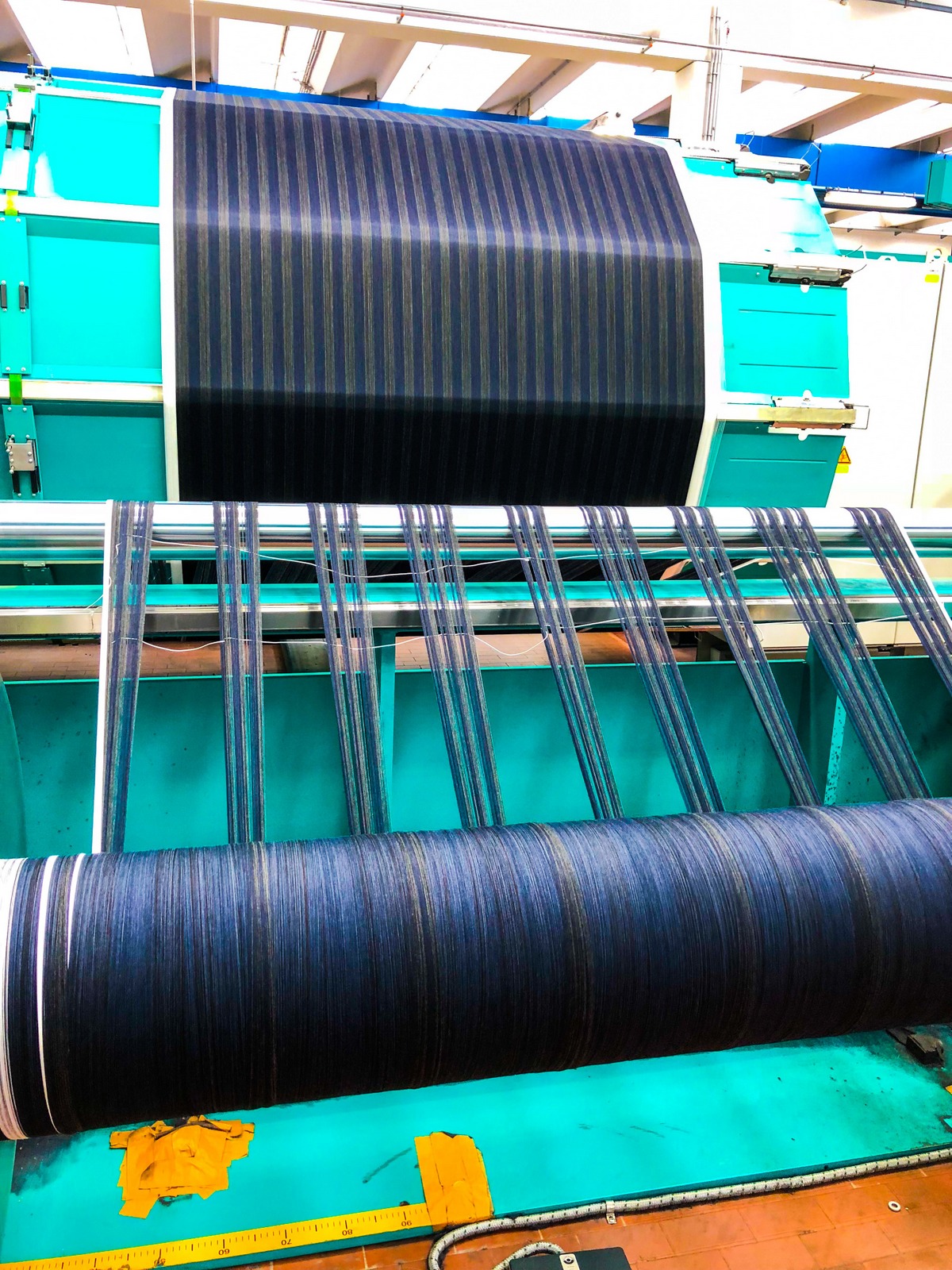

This next area is the sample room, I don’t remember if that’s what he called it. This team creates the small fabric swatches that I and a lot of others use to show clients suiting options. They were working on Fall 2019 samples while I was there so I will only show you a little bit.

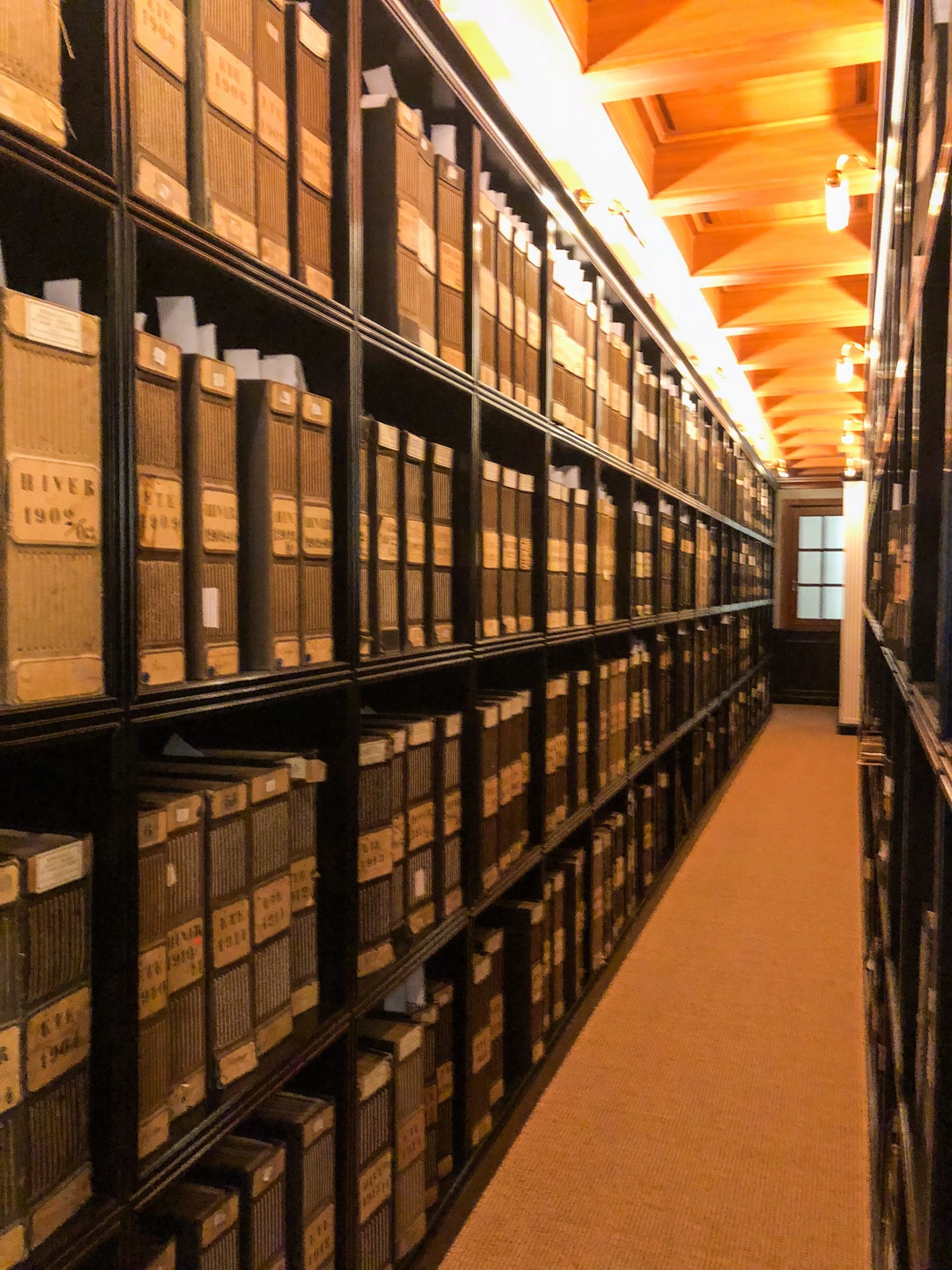

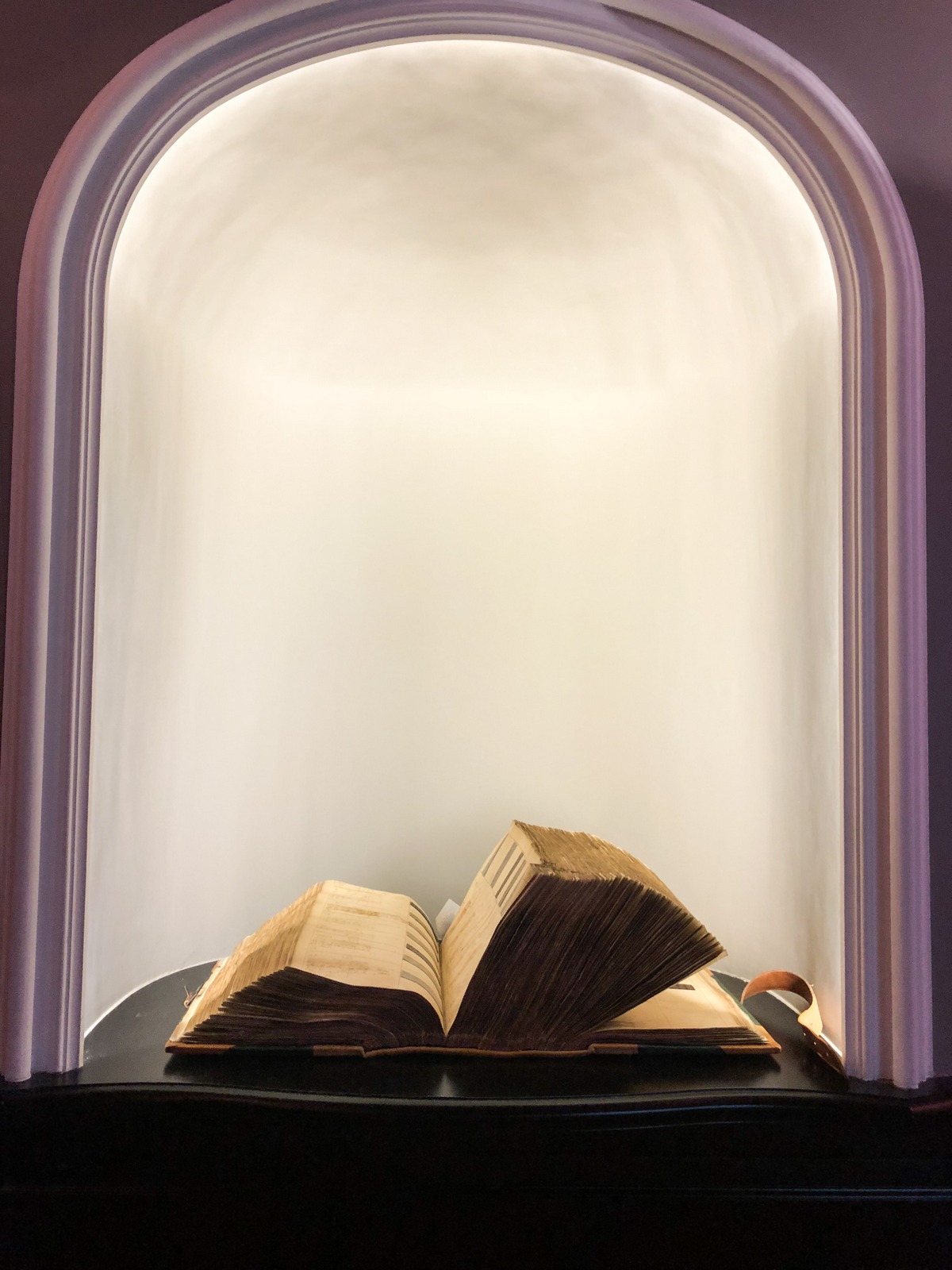

The Archive Room

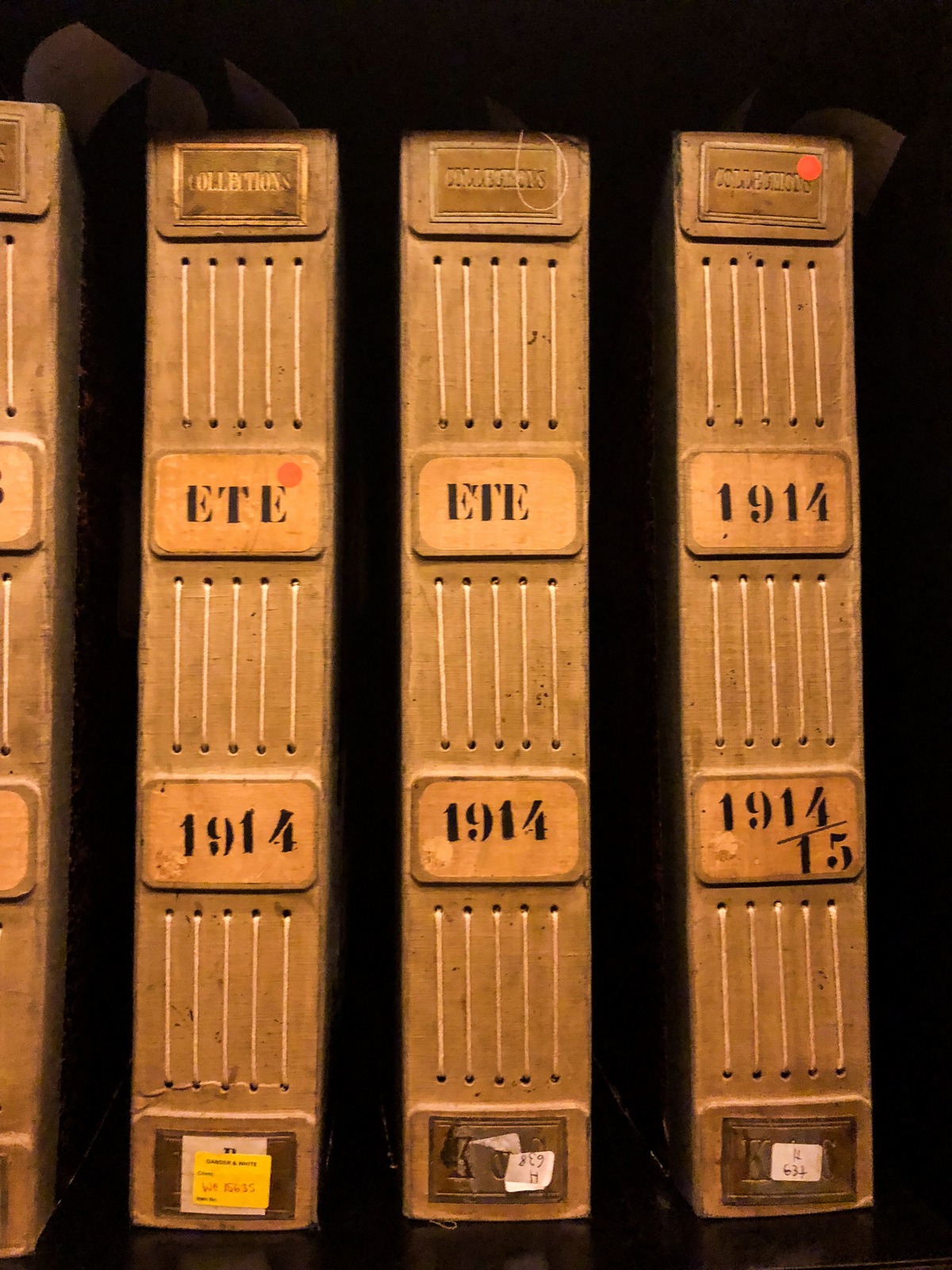

It is a one of a kind collection of over 2,000 volumes of ancient fabrics from Italy, France, United Kingdom, Germany and America. I had seen several of these books before, but to see them all in one place was pretty cool. The smell of the big leather binders and the history of fabrics within the pages down rows and rows of shelves was something to see. These books are used a reference for future designs and color combinations.

Thank you!!!

To the team at Vitale Barberis Canonico, it is an honor to put on my suit made from your hard work and attention to detail. Every guy who I sell a suit with your fabric will get to hear about how special this fabric really is and what it took to make it. It was truly a privilege to be there and thank you again, Marino, for talking time to show me around. Ciao!